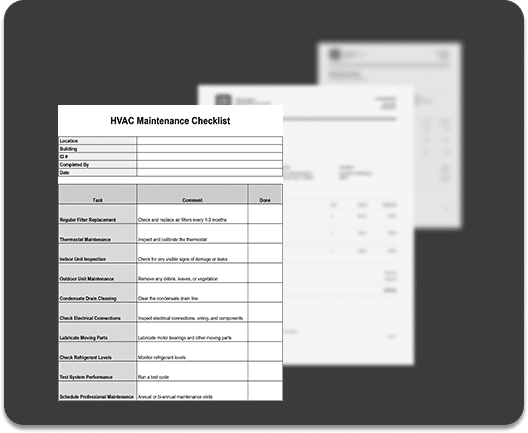

Creating a Preventive Maintenance Schedule

Creating an effective and efficient preventive maintenance schedule will largely depend on qualities that are specific to your organization, its assets, and even its customers. But there are some vital best practices any team should follow as they build their schedule:

Consider overall company goals

Every strategy your organization implements should align with broader company goals, and preventive maintenance is no exception. As you create your schedule, be sure to identify and share how a successful preventive maintenance approach will impact other business objectives; including increased productivity, reduced costs, and improved ROI. Be specific, and outline how each part of your schedule might contribute to larger organizational success.

Gather manuals and serial numbers

No two types of assets are exactly alike, so properly planning for their required maintenance means collecting all the information you can on each you intend to schedule for. Equipment manuals will guide your understanding of inspection frequencies and recommended repair or replacement procedures. Maintenance history data will shed light onto an asset’s reliability and risk for breakdowns. Make sure you also gather serial numbers, which will help you quickly and accurately order new parts should a piece of equipment fail.

Rank equipment and assets based on criticality

Next, you’ll need to prioritize the criticality of each of your assets to identify which of them will require immediate attention (and which can be put on the backburner in the case of failure).

Consider these questions as you rank your equipment:

- What is the projected impact of the asset’s failure? Will it compromise safety, stop production, or hurt the environment?

- Is the equipment reliable, or does it break down frequently?

- Is it easy to detect the issues caused by this asset’s failure, or would other connected systems also need to fail before you realize there’s a problem?

Organize labor resources

Each preventive maintenance activity will likely require different resources, time, and labor; and planning for each is crucial to the effectiveness of your schedule. These factors will help managers and staff schedulers assign jobs to each technician based on their relevant skill sets, locations, certifications, job history, preferences, and more.

Organize long- and short-term plans

As you hammer down the details of your maintenance plans, it’s best to start big and work your way down to the nitty-gritty. First, allow your prioritized list of your most critical assets to guide your long-term schedules. Use the manufacturers’ recommendations and the equipments’ reliability to establish regularly scheduled maintenance, dependent upon either time-based intervals, condition-based triggers, or usage-based benchmarks.

It’s important to note that these longer-term plans may need to be adjusted (depending on shifting business priorities, budget changes, etc.), so they should be treated as flexible outlines rather than set-in-stone strategies.

Next, create your short-term, weekly plans that support those longer-term efforts. Don’t forget: There will likely always be reactive maintenance issues that pop up now and again, so be sure your short-term schedules allow for those last-minute inevitabilities.

Train your team

A vital part of taking your preventive maintenance strategy from plan to action is, of course, getting your team on board with the change. Be as transparent as possible, and communicate all the reasons your new maintenance schedules will benefit your team, your organization, and your customers.

Provide in-depth training on any new tools, processes, and additional resources to avoid any confusion or resentment among team members. Make sure the systems you use allow for collaboration and knowledge transfer from tenured field techs to those new to the organization, so workers of every experience level are always prepared to complete the job. Remain open to feedback, too, since your technicians are the ones who are actually in the field performing these tasks on a daily basis. Document your training initiatives and outcomes so you can tweak them, as needed, as your team expands.

Track and adjust

Implementing a preventive maintenance strategy isn’t a one-and-done activity; rather, it’s an ongoing, continuously changing process that should be adjusted for optimal results. Reevaluate each asset, track and measure your data, and don’t be afraid to pivot if something’s not working.

Preventive Maintenance Software

It’s difficult—if not impossible—to establish and execute a strong preventive maintenance schedule if you’re using manual methods or tools. There’s simply too much to keep track of; and without the right software, things are bound to fall through the cracks.

Preventive maintenance software is technology that helps your team schedule maintenance activities, alert relevant team members when a task deadline is approaching, and more efficiently allocate resources. There are a few different types of software that can support your preventive maintenance efforts, so make sure you consider all your options before investing in a tool.

Computerized maintenance management systems (CMMS)

CMMS tools enable utilities organizations to easily track and manage their assets, equipment, and job histories in one, centralized place. With a strong CMMS, maintenance teams can keep track of and optimize their inventories and work orders.

Modern CMMS tools have features that:

- Automate work orders

- Create reports and audit records

- Manage workflows

- Provide operating and repair guidance

Enterprise resource planning (ERP)

ERP software connects data from every department across an organization, so everyone has access to the same processes and information. It acts as a centralized source of truth for finance, marketing, HR, sales, maintenance, and more, which means everyone is always working from the same information as they plan, analyze, and perform their daily functions.

While it’s true that an ERP system alone is likely not enough to support a successful preventive maintenance strategy, it can be used as part of the broader operation to bring everything together. Since it pulls in data from a variety of otherwise disparate sources, it’s an essential part of eliminating pesky duplicate data and ensuring accurate inventory.

Enterprise asset management (EAM)

Utilities companies use EAM tools to gain an end-to-end view of their organization’s physical assets. By providing information on each asset’s lifecycle (from procurement all the way to replacement or disposal), they help maintenance teams better coordinate and execute their preventive maintenance activities.

EAM tools have features that:

- Record asset information

- Manage work orders

- Track and organize the purchasing and usage of all inventory

- Measure costs and spending

- Track contracts

Bottom Line

A strong preventive maintenance operation can help your business reduce costs, boost worker productivity, and lengthen the life of crucial assets. It can better enable your maintenance teams to meet customer expectations and drive revenue as your organization scales.

But preventive maintenance software alone likely won’t cut it as you establish and execute your approach. For truly sustainable success, you also need technology that improves workforce visibility, ensures worker safety, and supports your multi-layered workflows and complex scheduling requirements. And you need to get the right worker to the right job site at the right time.

Skedulo’s scheduling software for energy and utilities companies helps teams reduce the operational inefficiencies and safety risks of poorly planned schedules. The cloud-based scheduling platform makes it easy to optimize scheduling and dispatching, so your field workers can get from one job site to the next quickly and safely. By combining intelligent skills matching functionality with route optimization, Skedulo can decrease your team’s scheduling time and ensure they never miss a maintenance task. The result is less service downtime, fewer safety risks, and a happier customer base.

Learn more about how Skedulo is transforming energy and utilities workforce management, or book a demo today.